How Custom Color-Mixing LEDs Are Made

When you see thousands of tiny lights dancing in sync - on a building façade, an immersive artwork, or a holiday spectacular - it’s easy to forget just how much detail goes into making them. Behind every glowing strand of faux neon or every perfectly calibrated RGB “bullet” pixel is a manufacturing process equal parts high-tech and handcrafted.

Here’s some insight straight from the production floor.

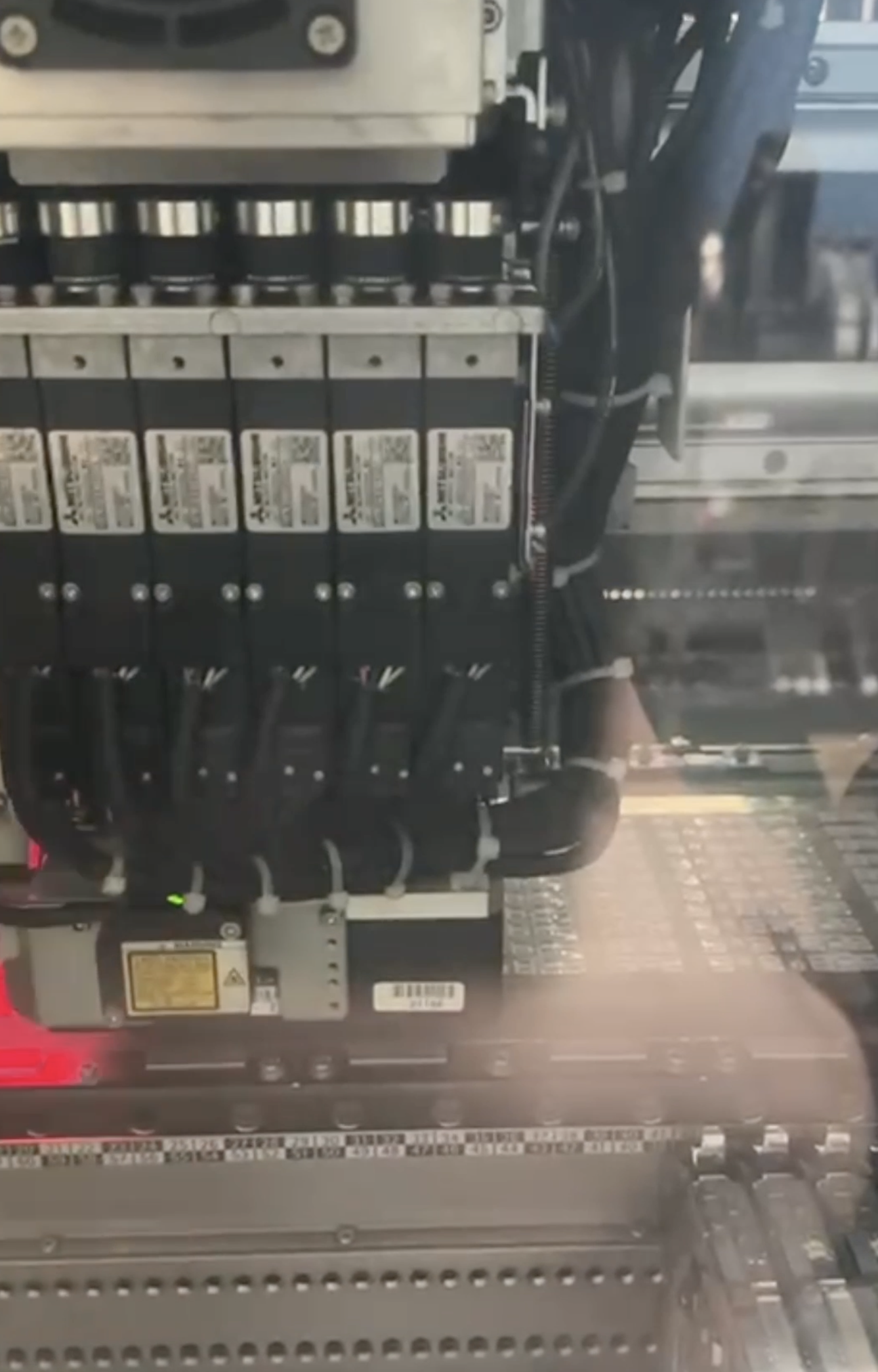

The Pick-and-Place Ballet

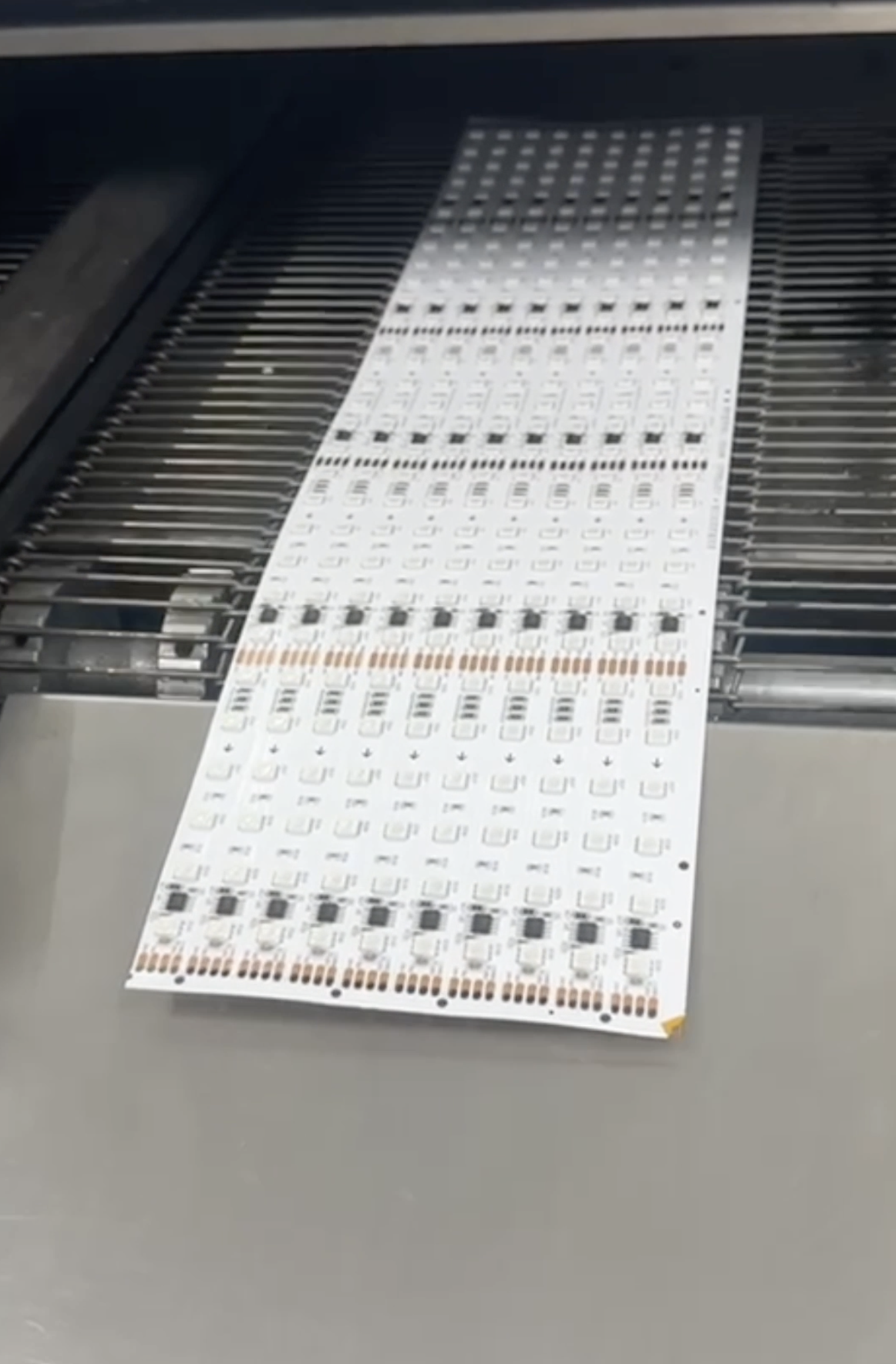

It all begins with printed circuit boards (PCBs). These are the backbone of nearly every LED product, and they’re assembled using a process called “pick-and-place.” A machine place each diode, resistor, and chip precisely where it belongs.

The boards then run through a solder flow process - like a high-tech oven -that fuses everything into place. Think of it as baking the perfect electronic cake.

The Human Touch

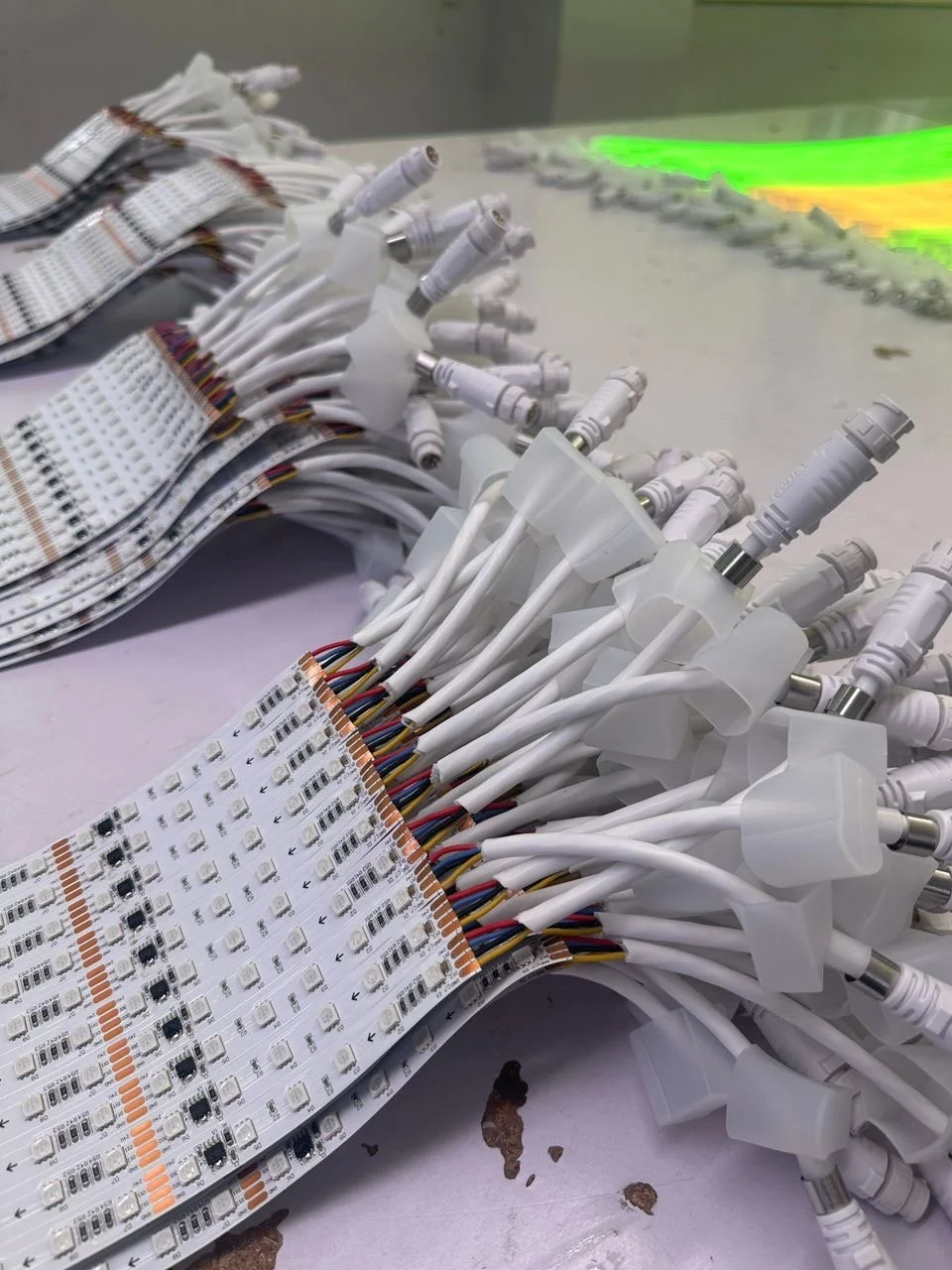

Not everything can be left to machines. Skilled technicians solder connections, align PCB’s, and crimp cables by hand. In the case of bullet pixels, each lead wire is anchored and sealed with resin to make sure it stands up to weather, vibration, and years of shows. Faux neon, meanwhile, is hand-fed with LED strips encased in its flexible housing.

Assembly at Scale

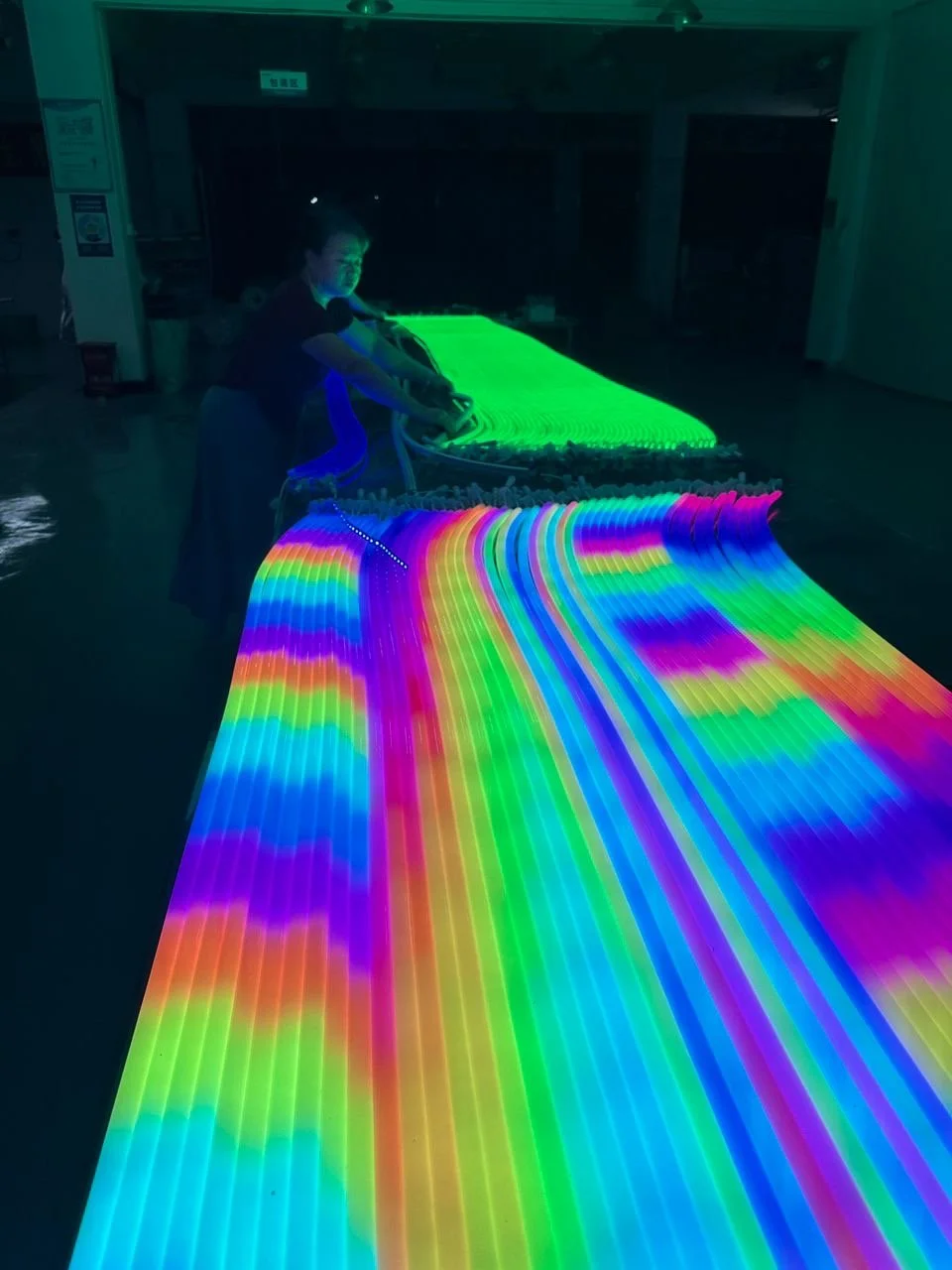

Once the subcomponents are built, it’s time for assembly. LED ribbons are coiled and prepped. Pixel strings are bundled into neat clusters. Connectors are crimped and tested, one by one, to ensure reliability. The repetitive, wave-like lines of light products stretching across a workbench look almost sculptural.

Burn-In Testing

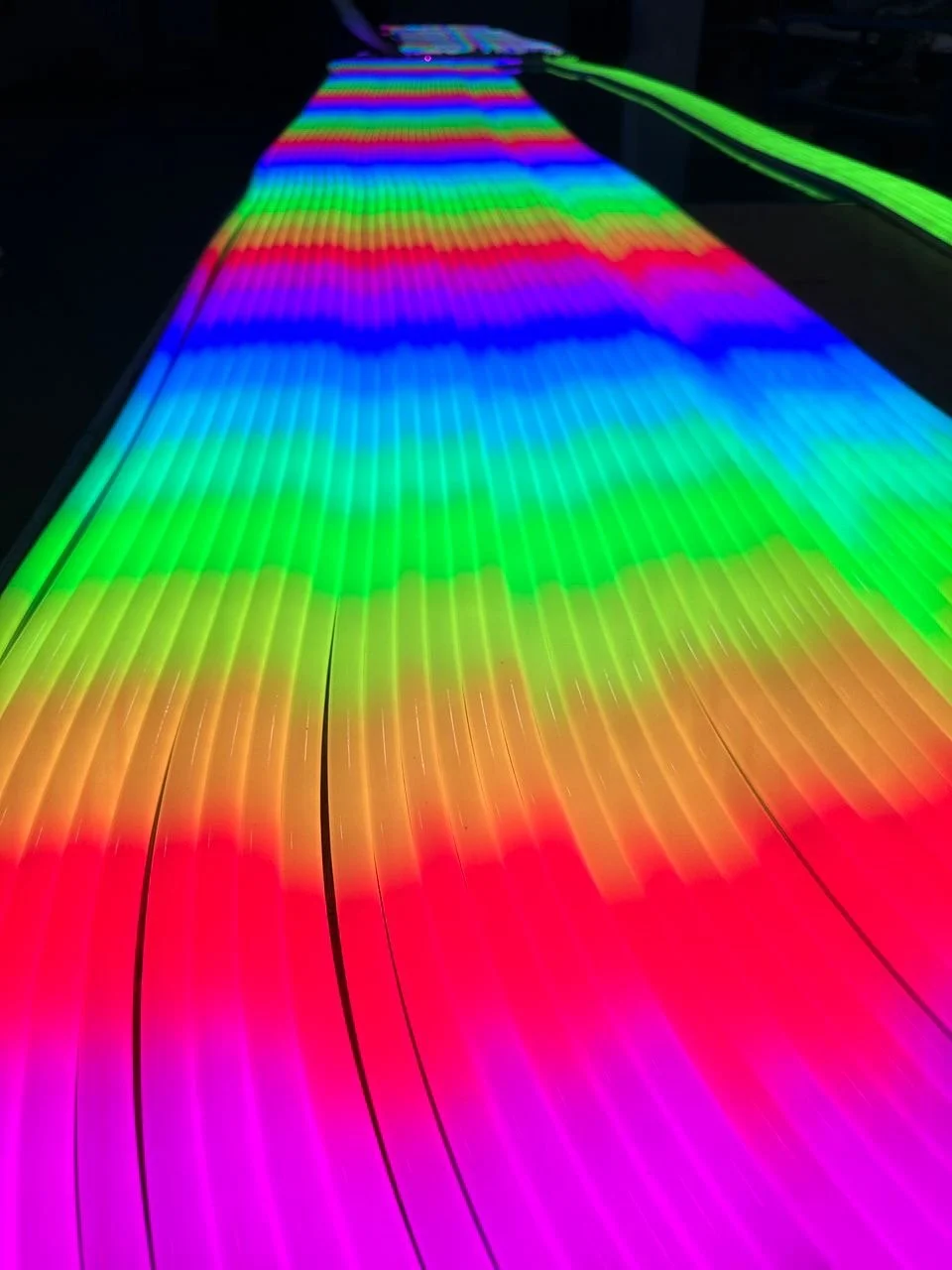

Before anything leaves the factory, it has to survive the “burn-in.” Rows of LEDs glow for hours, running through every color and intensity to expose any weak links. If a diode is going to fail, it’s better to fail now, under controlled conditions, than on a project site with a thousand guests watching.

The Submersion Test

Finally, waterproofing is put to the test. Strings of pixels are dunked in water while fully powered, proving their ability to endure rain, snow, and splash zones.

Why This Matters

Whether it’s faux neon bending around a storefront arch or pixels animating a building-sized holiday display, these components are the hidden heroes of modern, immersive storytelling. Each strand represents hundreds of careful steps—from robot precision to human craftsmanship to rigorous stress testing… the, hopefully… carefully-crafted programming.

You’ll see these very pixels on a couple exciting holiday projects, scheduled to open later this Fall in New York City - HUNDREDS OF THOUSANDS of “bullet'“ pixels and MILES of faux neon.

We can’t wait to share what we’ve been working on with our collaborators - American Christmas, AMA Electric Sign Co., and 4Wall Entertainment.

Thanks to the folks at Minleon USA for sharing these factory photos! A couple videos are available on our Instagram.